Fatty Alcohol Manufacturing Business - Navigating the Lucrative Landscape

In the realm of industrial chemicals, fatty alcohols stand out as versatile compounds with a wide range of applications across various industries. From personal care products to pharmaceuticals, from detergents to lubricants, the demand for fatty alcohols continues to soar, presenting lucrative opportunities for entrepreneurs in the manufacturing sector.

Introduction to Fatty Alcohol Manufacturing

Fatty alcohols are aliphatic alcohols derived from natural fats and oils, primarily sourced from palm kernel oil, coconut oil, and tallow. The manufacturing process involves the hydrolysis of triglycerides followed by fractional distillation to separate the fatty acids and alcohols. Subsequent hydrogenation converts the fatty acids into fatty alcohols, which are then purified to obtain the desired product. The process may vary depending on the desired carbon chain length and end-application requirements.

Fatty alcohols, a key component in various industrial applications, are integral to the production of personal care products, pharmaceuticals, detergents, and more. This thriving sector presents lucrative opportunities for entrepreneurs seeking to enter the chemical manufacturing industry. Understanding the market dynamics, manufacturing process, and applications of fatty alcohols is essential for navigating this business landscape successfully.

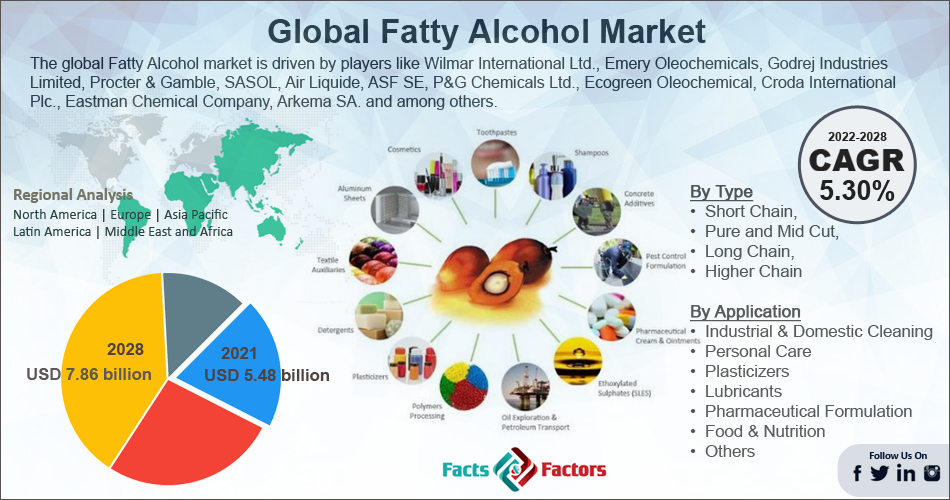

Market Overview

The global market for fatty alcohols has experienced substantial growth in recent years, driven by increasing demand from sectors such as personal care, pharmaceuticals, and household products. Fatty alcohols serve as crucial ingredients in the formulation of cosmetics, skincare products, medications, and cleaning agents. Their versatile properties, including emollient and surfactant characteristics, make them indispensable in various consumer and industrial applications.

In the personal care industry, fatty alcohols are used in moisturizers, lotions, shampoos, and conditioners to provide hydration, softness, and cleansing effects. Similarly, in the pharmaceutical sector, they find applications in ointments, creams, and topical medications for their soothing and emollient properties. Moreover, in the detergent industry, fatty alcohols serve as surfactants and cleansing agents in laundry detergents, fabric softeners, and dishwashing liquids.

The market for fatty alcohols is influenced by factors such as urbanization, changing consumer preferences, and the growing emphasis on sustainability. With increasing awareness about the environmental impact of chemical ingredients, there is a rising demand for bio-based and eco-friendly alternatives. Fatty alcohols derived from natural fats and oils are favored for their renewable and sustainable properties, driving market growth.

Manufacturing Process

Fatty alcohols are typically derived from natural fats and oils obtained from sources such as palm kernel oil, coconut oil, and tallow. The manufacturing process begins with the hydrolysis of triglycerides, followed by fractional distillation to separate fatty acids and alcohols. Subsequent hydrogenation converts the fatty acids into fatty alcohols, which are then purified to obtain the desired product.

During hydrogenation, unsaturated fatty acids are hydrogenated to saturate the carbon-carbon double bonds, resulting in the formation of saturated fatty alcohols. This process may involve catalytic hydrogenation under high pressure and temperature conditions. The final product is then subjected to purification steps to remove impurities and ensure product quality and consistency.

Overall, the fatty alcohol manufacturing process requires precise control of temperature, pressure, and reaction conditions to achieve optimal yields and product characteristics. With advancements in technology and process optimization, manufacturers can enhance production efficiency and meet the stringent quality standards of the industry.

Market Dynamics and Demand Trends

The global market for fatty alcohols has been witnessing steady growth, driven by increasing industrialization, urbanization, and changing consumer preferences. In the personal care sector, fatty alcohols serve as key ingredients in the production of cosmetics, skincare products, and hair care formulations. Their emollient properties make them ideal for moisturizers, creams, and lotions, while their surfactant properties enable their use in shampoos, conditioners, and body washes.

Similarly, in the pharmaceutical industry, fatty alcohols find applications in the production of ointments, creams, and topical formulations due to their soothing and moisturizing effects on the skin. Moreover, the detergent industry relies on fatty alcohols as raw materials for the manufacture of laundry detergents, fabric softeners, and dishwashing liquids, where they act as surfactants and cleansing agents.

Furthermore, the burgeoning demand for bio-based and eco-friendly products has fueled the growth of the fatty alcohol market. As consumers become more environmentally conscious, there is a growing preference for renewable and sustainably sourced raw materials, driving the adoption of fatty alcohols derived from natural oils and fats.

Opportunities and Challenges in Fatty Alcohol Manufacturing

The fatty alcohol manufacturing business presents significant opportunities for entrepreneurs looking to capitalize on the growing demand for these versatile compounds. With advancements in technology and process innovation, manufacturers can enhance production efficiency and product quality, thereby gaining a competitive edge in the market. Additionally, strategic partnerships with raw material suppliers and distribution channels can help streamline supply chains and expand market reach.

However, the industry also faces several challenges, including fluctuating raw material prices, stringent regulatory requirements, and environmental concerns associated with the production process. Moreover, competition from alternative surfactants and emollients poses a threat to market penetration and profitability. To overcome these challenges, manufacturers must focus on innovation, sustainability, and compliance with regulatory standards.

Conclusion

In conclusion, the fatty alcohol manufacturing business offers promising opportunities for entrepreneurs in the chemical industry. With growing demand across diverse end-user sectors and increasing emphasis on sustainability, the market for fatty alcohols is poised for continued growth in the coming years. By leveraging technological advancements, fostering strategic partnerships, and addressing key challenges, manufacturers can position themselves for success in this dynamic and thriving market.