Nicotine Manufacturing Business from Tobacco Waste - How to Start New Business

In recent years, there has been a growing interest in the extraction of nicotine from tobacco waste as a viable business opportunity. With the increasing demand for nicotine in various industries such as pharmaceuticals, e-cigarettes, and agriculture, establishing a manufacturing business in this niche sector holds immense potential. This guide aims to provide entrepreneurs with a detailed roadmap on how to start a successful nicotine manufacturing business using tobacco waste.

Tobacco smoking remains a significant contributor to premature deaths and health issues worldwide, with billions of cigarettes sold annually globally. Unfortunately, a considerable portion of these cigarettes are improperly disposed of, leading to the accumulation of toxic environmental waste. Among the most pervasive forms of tobacco waste is cigarette butts, compounded by the presence of cellulose acetate filters, a non-biodegradable plastic component attached to most commercially produced cigarettes. Despite its introduction by the tobacco industry under the guise of reducing perceived harm among smokers, these filters offer no tangible health benefits.

Addressing the economic implications of tobacco product waste is crucial for informing health policies, fostering environmental stewardship, and improving public health outcomes. Governments and societies stand to gain from comprehensive cost estimates associated with preventing, appropriately disposing of, and cleaning up tobacco product waste. Such estimates could serve as catalysts for the development of targeted interventions across health, environmental, and fiscal policy domains, thereby shifting accountability for the costs of tobacco product waste onto the global tobacco industry.

In light of these considerations, we advocate for an empirical approach to estimating the economic costs of tobacco product waste, grounded in its adverse environmental externalities. Our proposed methodology involves generating general cost estimates for six representative countries, while also identifying pertinent data gaps that necessitate attention for the development of global estimates. By quantifying the economic burden imposed by tobacco product waste, stakeholders can better advocate for policy interventions aimed at mitigating its detrimental effects.

Tobacco product waste extends beyond cigarette butts to include smokeless products, cigar remnants, packaging materials, and the refuse associated with electronic nicotine and non-nicotine delivery systems. Despite efforts by local governments, private businesses, and volunteers to address this issue through clean-up initiatives, tobacco waste continues to mar streets, sidewalks, beaches, parks, and other public spaces. Moreover, the flow of tobacco waste through storm drains and waterways poses significant contamination risks to aquatic ecosystems.

Combating tobacco product waste requires multifaceted interventions spanning health, environmental, and regulatory domains. By quantifying the economic costs associated with tobacco waste and raising awareness about its adverse impacts, we can advocate for policies that promote responsible consumption, proper disposal practices, and environmental stewardship. Through concerted efforts, we can work towards reducing the prevalence of tobacco use and mitigating its harmful consequences on public health and the environment.

Understanding the Market Demand:

Before diving into the intricacies of setting up a nicotine manufacturing business, it's crucial to grasp the market demand for nicotine and its derivatives. Nicotine is widely used in pharmaceutical products such as nicotine replacement therapy (NRT) patches, gums, and lozenges to aid in smoking cessation. Additionally, the burgeoning e-cigarette industry relies on nicotine for the production of e-liquids. Furthermore, nicotine-based pesticides are in demand in the agriculture sector due to their effectiveness against pests. Conducting thorough market research to identify potential customers and their needs is the first step in building a successful business strategy.

Regulatory Compliance and Licensing:

The nicotine manufacturing industry is subject to stringent regulations and licensing requirements to ensure product safety and quality. Entrepreneurs must familiarize themselves with the regulatory framework governing the production, storage, and distribution of nicotine and nicotine-containing products. This may include obtaining permits from local health authorities, adhering to Good Manufacturing Practices (GMP), and complying with labeling and packaging regulations.

Procuring Raw Materials:

The primary raw material for nicotine extraction is tobacco waste, which includes stems, stalks, and leftover leaves from tobacco processing facilities. Establishing reliable supply chains with tobacco farmers, growers, or tobacco companies is essential to ensure a steady and uninterrupted flow of raw materials. Additionally, entrepreneurs may explore partnerships with tobacco companies to procure tobacco waste at competitive prices.

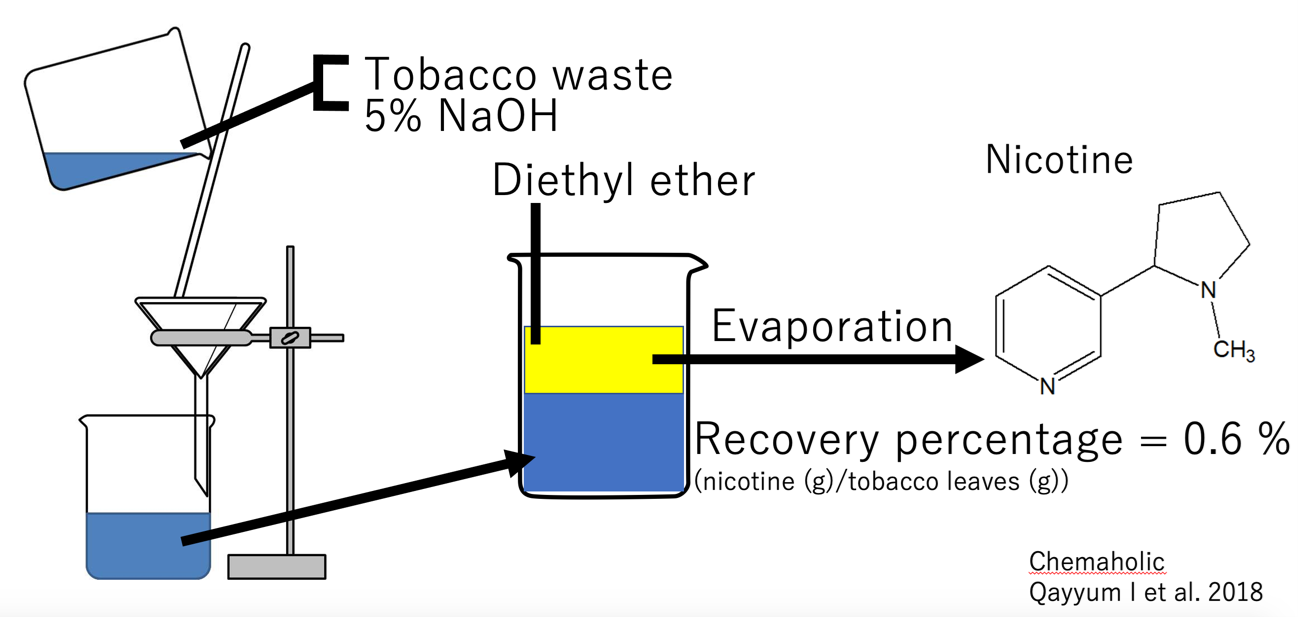

Extraction Process:

The extraction of nicotine from tobacco waste involves several steps, including maceration, solvent extraction, filtration, and purification. Various solvents such as ethanol or methanol are used to extract nicotine from the tobacco biomass, followed by filtration to remove impurities. The extracted nicotine undergoes further purification processes to achieve the desired level of purity required for different applications. Investing in state-of-the-art extraction equipment and ensuring adherence to safety protocols is crucial to maintaining product quality and efficiency.

Quality Control and Testing:

Ensuring the quality and purity of the extracted nicotine is paramount to the success of the manufacturing business. Implementing rigorous quality control measures and conducting regular testing at each stage of the production process is essential to meet industry standards and regulatory requirements. This may involve employing qualified chemists or technicians to perform analytical tests such as chromatography and spectroscopy to assess nicotine concentration and purity levels.

Packaging and Distribution:

Once the nicotine extract has undergone thorough quality control checks and testing, it is ready for packaging and distribution to customers. Entrepreneurs must invest in appropriate packaging materials that comply with regulatory guidelines and ensure product integrity during transportation and storage. Developing efficient distribution channels and establishing partnerships with distributors or wholesalers can help reach a wider customer base and penetrate new markets.

Marketing and Sales Strategy:

Effective marketing and sales strategies are crucial to building brand awareness and attracting customers to the nicotine manufacturing business. This may involve creating a compelling brand story highlighting the quality and purity of the nicotine extract, targeting specific customer segments such as pharmaceutical companies or e-cigarette manufacturers, and participating in industry trade shows and exhibitions to showcase products. Additionally, offering competitive pricing, discounts, and promotional offers can help gain a competitive edge in the market.

Conclusion:

Starting a nicotine manufacturing business from tobacco waste requires careful planning, strategic decision-making, and adherence to regulatory requirements. By understanding the market demand, investing in quality control measures, and implementing effective marketing strategies, entrepreneurs can establish a successful venture in this thriving industry. With the right combination of innovation, dedication, and perseverance, the journey from tobacco waste to valuable nicotine extract offers promising opportunities for growth and profitability in the manufacturing sector.