Makhana Production and Processing: A Complete Guide for New Entrepreneurs

Makhana, also known as fox nut or lotus seed, has quietly moved from being a traditional ingredient used in Indian homes to becoming one of the fastest-growing healthy snacks in the country. A few years ago, most people connected makhana only with religious fasting or home cooking. Today, shelves in supermarkets and online platforms are filled with roasted, flavored, and premium makhana packs. This shift has opened a strong business opportunity for anyone interested in food processing, especially because makhana gives high value addition at every stage. If you are planning to start an industry around makhana, it is important to understand how it is grown, how it is harvested, how processing works, what machinery is involved, and how the market is changing. This article walks you through all these aspects in a simple and practical way, helping you build a clear picture of what it takes to build a makhana business.

Understanding the Cultivation

Makhana is grown in still-water ponds and low-lying wetlands. These ponds have a soft muddy base, which gives the seeds the right environment to develop. Farmers usually plant the crop when temperatures begin to rise, and the plants spread across the water surface as they grow. Over time, broad leaves float on the water, and underneath them small fruits develop. Each fruit contains several hard black seeds. The ponds need regular monitoring so that weeds do not spread and water levels remain steady. Although makhana farming requires patience and labour, it is less risky compared to many field crops because water bodies naturally protect the crop from extreme weather. For an entrepreneur, the important thing to understand is that the supply of raw makhana depends heavily on specific regions, especially parts of Bihar and some pockets in Assam and Manipur. This means that if you start your unit in a different state, you may rely on sourcing raw seeds from these regions through traders or cooperatives.

Harvesting and Primary Handling

Harvesting makhana is completely different from harvesting crops on land. Farmers enter the pond on small boats or rafts and collect the mature fruits from the water. These fruits are then dried under sunlight for a short period, which helps harden the outer shell. Inside the shell is a very hard black seed that later becomes the white popped makhana. Once these seeds are collected, they must be cleaned thoroughly to remove mud and impurities. Proper primary cleaning is important because impurities affect popping quality and can slow down processing. Many farmers and small traders still do this work manually, while others use basic cleaning machines. As an entrepreneur, you should pay attention to the source of your raw seeds and ensure they are cleaned and sorted properly before they reach your unit. Cleaner raw seeds reduce wastage during roasting and popping.

The Processing Journey

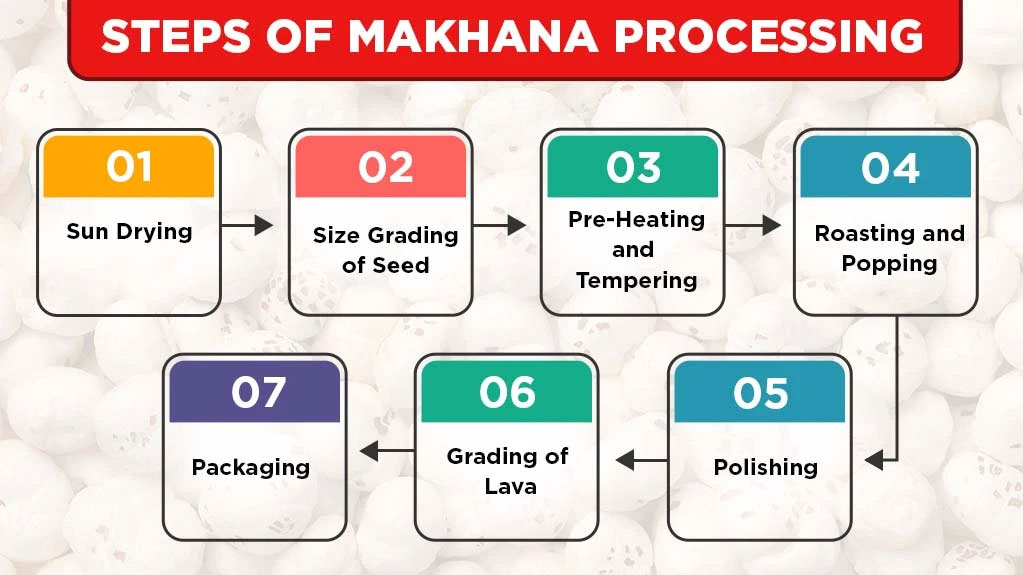

Processing is where the real transformation happens. Raw makhana seeds are hard and cannot be eaten directly. They have to undergo several steps before they become the light, fluffy snack everyone enjoys. The first major step is heating or roasting the seeds at high temperature. Traditionally, this was done by heating sand in a large pan and stirring the seeds through it. The high temperature helps loosen the inner core of the seed. Once this stage is complete, the seeds are cracked open manually or using machines. When the shell cracks, the inner white kernel can be separated. This kernel is then roasted again at high heat, which makes it pop. The popping is similar to how popcorn expands, but the process is more delicate and requires continuous movement of seeds to prevent burning. After popping, the makhana is allowed to cool, and then it is passed through grading equipment or manual selection to separate larger, medium, and smaller pieces.

Flavouring and Packaging

In today’s market, flavouring plays a big role. Plain makhana has a mild taste, but once it is roasted with different seasonings, it becomes a highly attractive snack. The flavouring process usually takes place in roasting drums or mixers where oil or ghee is used as a binding agent, and spices are added gradually so that the coating is even. After flavouring, the makhana is cooled to maintain crispness. Good cooling is important because if warm makhana is packed immediately, moisture can form inside the pouch and spoil the product. Packaging is the final step and one of the most important. The most commonly used pouches are laminated and air-tight. Many companies use nitrogen flushing to extend shelf life. A clean, attractive package is not just about protection; it affects how customers perceive the brand. For new businesses, simple but neat packaging works well in the beginning, and you can upgrade to premium versions as your brand grows.

Machinery and Facility Requirements

Setting up a makhana processing unit does not always require heavy machinery, but the right equipment improves efficiency and consistency. The basic machines include a cleaning unit, a roasting unit, a popping machine, grading equipment, a seasoning mixer, and a packaging machine. Some units also include small dryers to control moisture before popping. If you are planning a medium or large-scale setup, having a continuous roaster or hot-air popper can increase production capacity and ensure uniform quality. The facility itself should be well-ventilated, with a dry environment to prevent moisture from affecting the popped makhana. You also need separate sections for raw material storage, processing, flavouring, and packing so that hygiene is maintained. Depending on your scale, you may require FSSAI approval, a food-grade layout, and periodic quality testing for moisture, texture, and safety. Investing in skilled workers and supervisors also helps reduce wastage and improve product consistency.

- A makhana unit does not always need heavy industrial machines, but the right equipment increases efficiency and product consistency.

- Basic machines required are: a cleaning unit, a roasting unit, a popping machine, grading equipment, a seasoning mixer, and a packaging machine.

- Some setups also include small dryers to maintain proper moisture levels before popping.

- Medium and large units benefit from continuous roasters or hot-air poppers, which increase capacity and give uniform popping results.

- The facility should be well-ventilated and dry to protect popped makhana from moisture.

- Separate areas for raw material storage, processing, flavouring, and packing help maintain hygiene and smooth workflow.

- Depending on your scale, you may need FSSAI approval, a food-grade layout, and regular quality testing for moisture, texture, and safety.

- Skilled workers and supervisors play an important role in reducing wastage and maintaining consistent quality throughout the process.

Current Market Trends

The market for makhana has expanded rapidly because consumers are moving toward healthy snacking options. People are choosing roasted snacks over fried items, and makhana fits perfectly into this trend. The rise of e-commerce platforms has also given makhana brands a wider reach, helping them sell nationwide from day one. In addition to health-conscious buyers, families and young urban consumers are adopting makhana because it is easy to carry, has a long shelf life, and comes in several flavours. Another strong trend is the premiumization of makhana. Many brands are introducing gourmet variants such as caramel, cheese, herbs, and chocolate coating. These products attract higher prices and appeal to gifting and festive markets. The growth of fitness culture in India has also helped makhana, as gyms, wellness influencers, and dieticians often recommend it as a protein-rich and low-calorie snack. All these trends indicate that makhana is not a passing phase but a long-term opportunity.

Export Potential and Global Demand

The international market for makhana is still developing but has strong potential. Indian communities living abroad already buy makhana, and now non-Indian consumers are becoming aware of it as a healthy snack. Several Western countries are slowly adding makhana to organic food stores and health aisles. Export demand is growing especially in the US, UK, Canada, Australia, and Gulf countries. For entrepreneurs who want to tap into this opportunity, maintaining high-quality standards is crucial. Export products require strict packaging norms, clean ingredient lists, and consistency in size and popping quality. As more people around the world look for natural, gluten-free, and plant-based snacks, makhana fits well into their dietary preferences. If India can scale organized production and processing, it can become the global hub for makhana export.

Financial Outlook and Profit Possibilities

One of the reasons makhana processing attracts new entrepreneurs is the clear difference between raw material cost and final product value. Raw seeds have a steady price, but once they are popped, flavoured, and packed, their value increases several times. Even a basic processing unit can generate a good margin if it maintains low wastage and stable quality. The biggest cost elements include raw seeds, fuel or electricity for roasting, labour, packaging materials, and transportation. If you buy raw seeds in bulk during the harvest season, you may get better rates. Selling branded makhana directly to consumers through online platforms also gives higher margins compared to wholesale. Many new entrepreneurs start small, build a customer base, and then expand their machinery and facility as demand rises. With proper planning and steady marketing, a makhana unit can achieve break-even within a few months to a year, depending on scale and investment.

Challenges in the Industry

Every industry has its challenges, and makhana is no exception. The first challenge is sourcing. Since makhana farming is region-specific, supply can fluctuate. If you are located far from the growing regions, you must build a good relationship with suppliers or traders to ensure steady supply. The second challenge is consistency in popping. Not all raw seeds pop equally, and quality varies from batch to batch. You need trained workers and reliable equipment to maintain uniformity. Another challenge is competition. Many new brands have entered the market in the last few years, especially in the flavoured category. To stand out, you must focus on freshness, honest pricing, attractive packaging, and dependable taste. Marketing can be time-consuming, and convincing retailers to give shelf space may take effort. However, most of these challenges can be managed with proper planning, strong supplier networks, and clear brand positioning.

Future Prospects and Opportunities

The future of makhana looks bright because consumer habits are changing in favour of healthier snacks. The demand for plant-based and gluten-free foods is rising every year, and makhana fits naturally within these trends. There is also a growing interest in traditional Indian foods with modern packaging, which works in favour of makhana brands. Another area of opportunity is ready-to-cook and ready-to-eat formats. Some companies have started introducing makhana curry mixes and powdered makhana for breakfast dishes. The beauty and wellness industry is also exploring makhana extracts for skin and health products. With the right research and partnerships, entrepreneurs can expand beyond snacks into value-added products. As the government continues to support food processing and create cold-chain infrastructure, makhana units can benefit from subsidies, schemes, and technology upgrades. Overall, the next few years are likely to bring strong growth, deeper market penetration, and wider global acceptance of makhana.

Trend Insights: Makhana Flavours, Packaging & Export Demand

The flavour segment in the makhana industry is expanding at a fast pace. Earlier, only basic roasted varieties were common, but now brands are experimenting with bolder and richer tastes like cheese, peri-peri, herbal mixes, and even chocolate coatings. Alongside these, there is a growing interest in makhana enriched with ingredients such as ashwagandha, plant protein, or other wellness blends, which appeals to health-focused buyers.

- A strong shift toward clean-label snacks is also shaping the flavour trend. Consumers prefer seasonings that feel natural and simple, such as sea salt or mild herb mixes, rather than artificial additives. This demand is encouraging manufacturers to use fewer chemical ingredients and focus on higher-quality seasoning materials.

- Organic makhana is carving out its own space in the market. Both Indian and international buyers are willing to pay a premium for makhana that is grown without chemicals. This push for cleaner farming practices is motivating many cultivators to follow organic or eco-friendly cultivation methods, especially in states like Bihar where makhana farming is prominent.

- Packaging trends are changing rapidly to meet modern expectations. Resealable pouches, recyclable materials, and biodegradable packaging options are becoming popular, especially in the premium category. Buyers today want snacks that stay fresh longer and come in packaging that aligns with sustainability values.

- Smaller pack sizes are also becoming a big hit. Single-serve pouches, mini ready-to-eat cups, and compact snack bowls are gaining momentum among working professionals, gymgoers, and students who want convenient, portion-controlled snacks.

- On the global front, the appetite for roasted and flavoured makhana continues to rise. Larger-size kernels and high-grade popped makhana are particularly valued in international markets. Export numbers have grown significantly over the last few years, showing that buyers abroad see makhana as a clean, plant-based snack with strong nutritional benefits.

- Countries in North America and Europe are emerging as major buyers. As plant-based snacking becomes more mainstream there, makhana fits naturally into the category and competes well with popcorn, corn puffs, and trail mixes.

- Export buyers are increasingly paying attention to how the product is grown and packed. Certifications for organic farming, proof of traceability, and environmentally-conscious packaging play a key role in securing overseas orders. This is pushing Indian processors to upgrade their systems and maintain proper documentation.

- Government backing is also strengthening the export potential. New schemes, state-level initiatives, and investments in processing clusters are helping improve quality control, storage, and branding, which makes Indian makhana more competitive in global markets.

- Market projections for the coming years remain positive. Estimates suggest that makhana demand will continue to grow steadily, with India’s domestic industry expected to expand at close to 9% annually through the late 2020s.

New business ideas are also entering the space. More companies are exploring private-label manufacturing, B2B export supply, subscription snack boxes, and direct partnerships with international distributors. This variety of business models gives new entrepreneurs more ways to enter the sector.

However, climate factors cannot be ignored. Since makhana cultivation depends on pond systems and water availability, unpredictable rainfall and rising temperatures may pose challenges in future. Many producers are beginning to adopt water-efficient farming practices and resilient cultivation methods to reduce these risks.

Complete Technology Handbook on Makhana (Fox Nuts) Production and its Processing with Project Profiles (Cultivation, Harvesting, Roasting, Machinery, Market, Flavours)

This book presents a comprehensive, end-to-end exploration of Makhana, offering a complete reference for farmers, researchers, food technologists, processors, entrepreneurs, and policymakers seeking to understand and participate in this fast-growing sector.

- The first part of the book lays the botanical and agricultural foundation by exploring lotus seeds in detail—their structure, nutritional chemistry, bioactive components, and the wide range of Makhana varieties available today. It explains how Makhana is traditionally harvested, dried, roasted, popped, and polished, and contrasts traditional practices with modernized field-based cultivation systems. These chapters also highlight the ecological requirements, regional production hubs, and government efforts supporting Makhana cultivation.

- The second part focuses on the cultivation environment and integrated systems. It covers pond and field ecosystems, sowing and nursery practices, field preparation, transplantation, and water management. Readers are introduced to the complete growth and harvesting cycle of the crop, the benefits of integrated farming with fish and water chestnut, and the challenges posed by climate, manual labor, and traditional tools. Modern production steps—grading, tempering, roasting, polishing, and packaging—are explained in detail.

- The third part examines the economic and technological pillars of the industry. It analyzes the role of Makhana in rural employment, government schemes, and value chains, while addressing processing constraints and the need for mechanization. Updated technologies, including advanced popping machines, washing and drying systems, roasters, graders, seasoning and packaging machines, are presented along with innovations aimed at improving efficiency, safety, and scalability.

- Scientific insights take center stage in the fourth part, which discusses the physical, chemical, nutritional, and functional properties of Makhana. This includes nutrient composition, antioxidant potential, Ayurvedic significance, bioactive metabolite identification through HR-MS, and detailed physical characterizations such as density, texture, aerodynamic behavior, and hygroscopic nature. The book also examines sensory evaluation, product quality, and the application of Makhana in bakery and other food systems.

- The fifth part explores the expanding world of value-added products and market opportunities. With global demand rising, Makhana is finding new applications in snack foods, bakery products, nutritional supplements, ready-to-eat meals, and international trade. The book provides insight into product diversification—ranging from roasted and flavored snacks to vermicelli, flour, chips, and kheer mixes—along with standards for grading, quality assessment, and competitive industry dynamics influenced by substitutes, consumer trends, and technological shifts.

- Entrepreneurs and MSMEs will find the sixth part especially valuable, as it outlines government schemes such as PMFME, ODOP, and Makhana-specific initiatives. Detailed guidance is provided on business planning, sourcing, processing unit setup, flavor innovation, quality control, packaging, distribution channels, export opportunities, and compliance with regulatory frameworks. Important statutory requirements—GST, IEC, factory licenses, pollution control, FSSAI registration, GMP, GHP, and HACCP—are covered exhaustively to support responsible and sustainable enterprise development.

- The final part of the book highlights technological innovation, flavor development, export potential, and plant economics for processing and value addition. It presents guidance on unique product creation, including Peri Peri Makhana and other modern flavor profiles, and offers detailed financial insights related to capital investment, machinery, operational costs, turnover, and profitability. This section equips new and existing enterprises with the information needed to evaluate investment feasibility and achieve long-term success.

Taken together, this book offers a 360-degree view of the Makhana ecosystem—its biology, cultivation, processing, value addition, quality standards, markets, policies, and business opportunities. It aims to serve as a definitive guide at a time when Makhana is gaining global attention as a nutritious, sustainable, and economically transformative crop. It is my hope that this work will empower all stakeholders to better understand, cultivate, process, innovate, and commercialize Makhana, contributing to the growth of this extraordinary superfood industry.

Conclusion

Starting a makhana processing industry is a promising business idea for entrepreneurs who want to enter the food sector with a product that already has strong demand. With proper understanding of the cultivation cycle, harvesting methods, processing stages, machinery requirements, and market trends, you can set up a unit that produces high-quality makhana consistently. The market is expanding at a steady pace, driven by health awareness, new flavours, modern packaging, and rising export interest. While challenges such as sourcing, competition, and quality control exist, they can be handled with thoughtful planning and good management. What makes makhana attractive is its ability to turn a simple agricultural seed into a premium consumer product with excellent margins. Whether you start a small unit or aim for a large-scale operation, makhana gives you a strong foundation to build a sustainable and profitable business in the growing healthy-snack industry.