Onion Processing Business - Onion Based Business Ideas

Onions are a staple ingredient in cuisines around the world, prized for their versatility and distinct flavor profiles. From fresh salads to savory stews, onions play a crucial role in countless recipes. However, before they reach consumers' plates, onions undergo a series of processing steps to ensure quality, shelf-life, and convenience. In this comprehensive guide, we'll explore the various aspects of starting an onion processing business, from sourcing raw materials to marketing finished products.

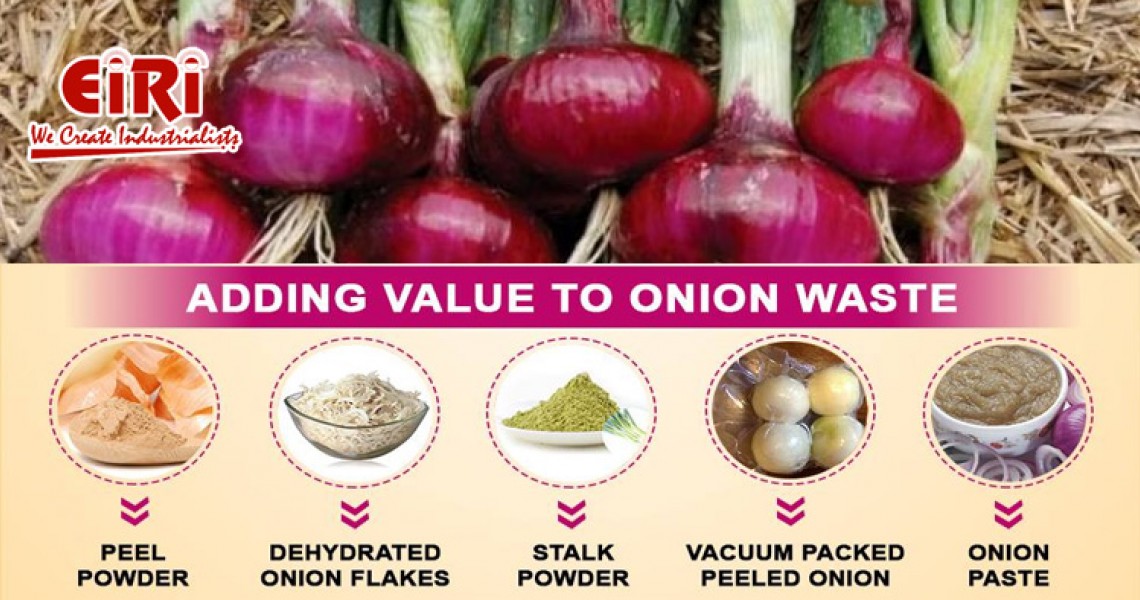

Understanding Onion Processing and Onion Based Products:

Onion processing involves several stages, each aimed at transforming raw onions into value-added products suitable for various culinary applications. The primary processing steps include cleaning, peeling, slicing, dicing, and drying. Additionally, onions can be processed into powdered forms, extracts, or pickled products, catering to diverse market demands.

There are numerous onion-based products that entrepreneurs can consider manufacturing and selling. Here are some popular options:

Onion Powder:

Onion powder is a versatile ingredient used in a wide range of culinary applications, including seasoning blends, soups, sauces, and marinades. Manufacturing onion powder involves dehydrating and grinding onions into a fine powder, which offers convenience and extended shelf life.

Onion Flakes:

Onion flakes are dehydrated onion pieces that retain their flavor and aroma. They can be used as a convenient alternative to fresh onions in various dishes, such as casseroles, stir-fries, and salads. Manufacturing onion flakes involves dehydrating sliced onions to remove moisture while preserving flavor and nutrients.

Onion Paste:

Onion paste is a concentrated form of onions that adds depth and richness to dishes. It can be used as a base for sauces, gravies, and marinades, providing flavor and aroma without the need for chopping or sautéing fresh onions. Manufacturing onion paste involves grinding fresh onions into a smooth paste and packaging it for retail sale.

Pickled Onions:

Pickled onions are onions that have been preserved in a brine or vinegar solution, resulting in a tangy and flavorful condiment. They can be served as a topping for sandwiches, salads, or charcuterie boards. Manufacturing pickled onions involves soaking onions in a vinegar-based brine with herbs and spices before packaging them in jars for retail sale.

Onion Chutney:

Onion chutney is a savory condiment made from cooked onions, spices, and vinegar or lemon juice. It adds a burst of flavor to sandwiches, wraps, and Indian dishes such as dosas and idlis. Manufacturing onion chutney involves cooking onions with spices and other ingredients, blending them into a smooth paste, and packaging for retail sale.

Onion Jam:

Onion jam is a sweet and savory spread made from caramelized onions, sugar, and vinegar. It pairs well with cheeses, charcuterie, and grilled meats, adding a unique flavor profile to dishes. Manufacturing onion jam involves slow-cooking onions with sugar and vinegar until they caramelize and thicken into a jam-like consistency.

Onion Soup Mix:

Onion soup mix is a blend of dehydrated onions, herbs, and seasonings used to flavor soups, dips, and casseroles. It offers convenience and flavor enhancement for home cooks and foodservice establishments. Manufacturing onion soup mix involves blending dehydrated onions with spices and packaging them for retail sale.

Onion Oil:

Onion oil is a popular ingredient in aromatherapy and skincare products due to its purported health benefits and skin-nourishing properties. It can also be used in culinary applications to add flavor to dishes. Manufacturing onion oil involves extracting the essential oils from onions through a distillation process and packaging it for retail sale.

How to Start Onion Processing Based Business

Market Analysis:

Before diving into onion processing, it's essential to conduct a thorough market analysis to identify potential opportunities and challenges. Analyze consumer preferences, market trends, and competitor offerings to develop a strategic business plan. Consider factors such as regional demand, distribution channels, and pricing strategies to position your products effectively in the market.

Sourcing Raw Materials:

The success of an onion processing business hinges on sourcing high-quality raw materials. Partner with reputable onion suppliers or cultivate your own onions to ensure consistent quality and supply. Consider factors such as onion varieties, growing conditions, and seasonal availability when sourcing raw materials to meet production requirements year-round.

Processing Equipment and Infrastructure:

Invest in the right processing equipment and infrastructure to streamline operations and ensure product quality. Key equipment may include onion cleaning machines, peeling machines, slicing and dicing equipment, drying ovens, and packaging machinery. Design a layout that optimizes workflow efficiency and adheres to food safety and hygiene standards.

Food Safety and Quality Assurance:

Maintaining food safety and quality assurance is paramount in onion processing. Implement robust hygiene practices, sanitation protocols, and quality control measures throughout the production process. Adhere to regulatory standards and certifications to instill consumer confidence and meet market requirements.

Product Development and Innovation:

Differentiate your onion processing business by offering a diverse range of products tailored to consumer preferences. Experiment with flavor profiles, textures, and packaging formats to create unique offerings that stand out in the market. Stay abreast of industry trends and consumer insights to drive product innovation and maintain a competitive edge.

Packaging and Branding:

Effective packaging and branding play a crucial role in attracting consumers and building brand loyalty. Choose packaging materials that preserve product freshness and appeal to target demographics. Invest in visually appealing labels, logos, and marketing materials that communicate your brand story and value proposition effectively.

Distribution and Marketing:

Develop a robust distribution network to reach target markets efficiently. Explore partnerships with wholesalers, retailers, and foodservice providers to expand your reach and maximize sales opportunities. Implement multi-channel marketing strategies, including digital marketing, social media promotion, and participation in trade shows or industry events, to raise awareness and generate demand for your products.

Compliance and Regulatory Considerations:

Navigate regulatory requirements and compliance standards governing food processing operations. Obtain necessary permits, licenses, and certifications to operate legally and ensure adherence to food safety regulations. Stay informed about industry updates and changes in regulations to maintain compliance and mitigate risks associated with non-compliance.

Conclusion:

Starting an onion processing business presents lucrative opportunities for entrepreneurs looking to enter the food processing industry. By understanding the intricacies of onion processing, investing in quality equipment and infrastructure, prioritizing food safety and quality assurance, and implementing effective marketing and distribution strategies, you can establish a successful and sustainable onion processing venture. With careful planning, innovation, and dedication to excellence, your onion processing business can thrive in today's competitive marketplace.