Starting an Electric Vehicle Battery Manufacturing Unit: What You Need to Know

The electric vehicle (EV) industry is experiencing unprecedented growth, driven by the global push towards reducing carbon emissions and transitioning to sustainable transportation. At the heart of every electric vehicle is its battery, which serves as the primary source of power. EV batteries are complex systems that require advanced technology, high-quality materials, and precise manufacturing processes. As the demand for electric vehicles continues to rise, the need for efficient and reliable EV batteries is also increasing. For entrepreneurs and manufacturers, this presents a lucrative opportunity to enter a rapidly expanding market. This guide will explore the key aspects of starting an electric vehicle battery manufacturing unit, from understanding the technology to navigating the production process and market dynamics.

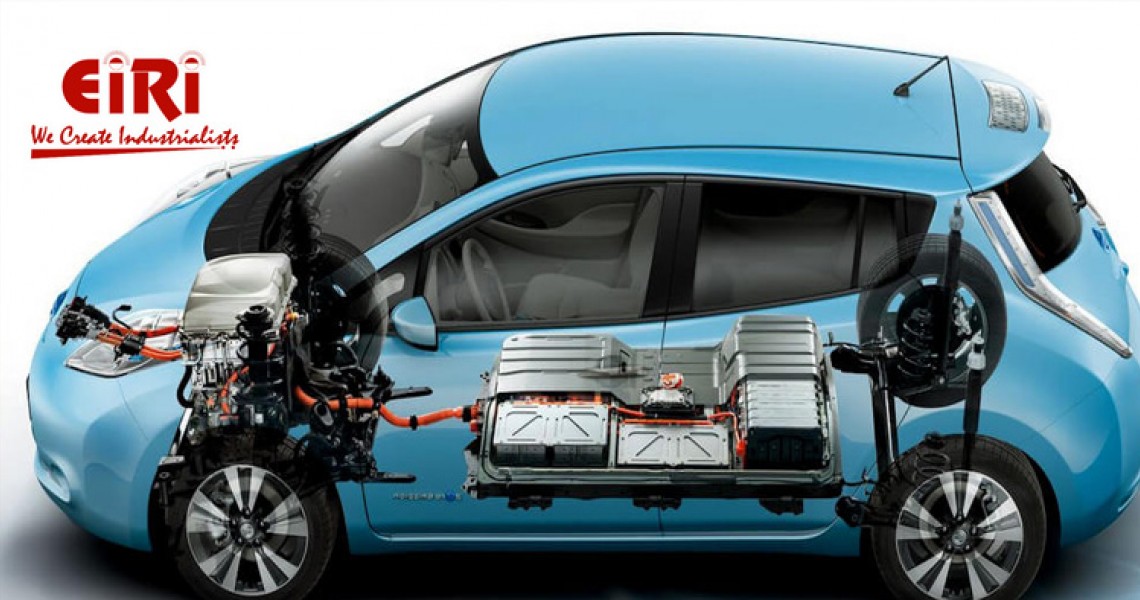

Electric vehicle batteries are typically lithium-ion batteries, known for their high energy density, long cycle life, and relatively low self-discharge rate. These batteries consist of several key components, including the cathode, anode, electrolyte, separator, and casing. The cathode is usually made from lithium metal oxides such as lithium iron phosphate (LFP) or lithium nickel manganese cobalt oxide (NMC). The anode is typically made from graphite, while the electrolyte is a lithium salt in an organic solvent. The separator is a porous membrane that prevents the cathode and anode from coming into direct contact, while the casing provides structural support and protection.

The performance of an EV battery is determined by several factors, including energy density, power density, cycle life, and safety. Energy density refers to the amount of energy stored per unit of weight or volume, while power density refers to the rate at which energy can be delivered. Cycle life is the number of charge-discharge cycles a battery can undergo before its performance degrades, and safety involves measures to prevent issues such as overheating, short circuits, and thermal runaway. Understanding these factors and the technology behind EV batteries is essential for setting up a successful manufacturing unit.

Market Research and Feasibility Study

Before diving into the manufacturing process, it is crucial to conduct thorough market research and a feasibility study. Understanding the market landscape, including current trends, customer needs, and competitive analysis, will help you identify opportunities and challenges. The demand for EV batteries is driven by factors such as government incentives, declining costs of battery technology, and increasing consumer adoption of electric vehicles. Automotive manufacturers are looking for reliable and high-performance batteries to power their electric vehicles, while energy storage companies are seeking batteries for grid storage and renewable energy integration.

A feasibility study should also assess the technical and financial aspects of starting an EV battery manufacturing business. This includes evaluating the availability of raw materials, the complexity of the manufacturing process, and the required capital investment. EV battery production requires specialized equipment and expertise, as well as access to high-quality materials such as lithium, cobalt, nickel, and graphite. Additionally, the manufacturing process involves several stages, including electrode production, cell assembly, and testing, each requiring precision and quality control. Conducting a thorough feasibility study will help you determine the viability of your business idea and develop a realistic business plan.

Sourcing Raw Materials and Components

The production of EV batteries begins with the sourcing of high-quality raw materials and components. The key materials include lithium, cobalt, nickel, and graphite, which are used to produce the cathode, anode, and electrolyte. Lithium is the most critical material, as it is the primary component of the electrolyte and cathode. Cobalt and nickel are used in the cathode to enhance energy density and stability, while graphite is used in the anode. Sourcing these materials from reliable suppliers is essential for ensuring the consistency and performance of your batteries.

In addition to the raw materials, other components such as separators, binders, and conductive additives are required to produce the electrodes and assemble the battery cells. The separator is a porous membrane that prevents the cathode and anode from coming into direct contact, while binders are used to hold the active materials together. Conductive additives, such as carbon black, are used to enhance the electrical conductivity of the electrodes. Establishing strong relationships with suppliers and negotiating favorable terms can help you manage costs and maintain a steady supply chain.

Setting Up the Manufacturing Unit

Setting up an EV battery manufacturing unit involves several key steps, including selecting a suitable location, acquiring the necessary equipment, and hiring skilled personnel. The location of your manufacturing unit should be chosen based on factors such as proximity to raw material suppliers, access to transportation networks, and availability of skilled labor. Additionally, the facility should have adequate space for production lines, storage, and quality control laboratories.

The equipment required for EV battery manufacturing includes electrode coating machines, cell assembly lines, and testing equipment. Electrode coating machines are used to apply the active materials onto the current collectors, while cell assembly lines are used to assemble the electrodes, separators, and electrolytes into battery cells. Testing equipment is used to evaluate the performance, durability, and safety of the batteries. Investing in high-quality equipment is essential for ensuring the efficiency and reliability of your production process.

Hiring skilled personnel is another critical aspect of setting up your manufacturing unit. The production of EV batteries requires expertise in areas such as materials science, chemical engineering, and quality control. Training your workforce and implementing standard operating procedures (SOPs) will help ensure consistent product quality and efficient operations. For beginners, partnering with experienced professionals or consultants can provide valuable insights and guidance in setting up and managing your manufacturing unit.

Manufacturing Process of EV Batteries

The manufacturing process of EV batteries involves several stages, each requiring precision and expertise. The first stage is the production of the electrodes, which involves mixing the active materials with binders and conductive additives to form a slurry. The slurry is then coated onto the current collectors, usually made of aluminum or copper foil, and dried to remove solvents. The coated foil is then calendared to achieve the desired thickness and density. The next stage is the assembly of the battery cell, which involves stacking the electrodes, separators, and electrolytes in a specific configuration. This assembly is then placed in a casing, typically made of aluminum or steel, and sealed to prevent leakage.

The final stage is the formation and testing of the battery. Formation involves charging and discharging the battery to stabilize its performance and capacity. This step is crucial for ensuring the battery's longevity and reliability. After formation, the battery undergoes rigorous testing to evaluate its performance, including capacity, cycle life, and safety. Advanced testing equipment and protocols are essential to ensure that the batteries meet industry standards and customer expectations. For beginners, it is advisable to start with a small-scale production line and gradually scale up as you gain experience and market traction.

Quality Control and Certification

Quality control is a critical aspect of EV battery manufacturing, as it directly impacts the performance, safety, and reliability of the batteries. Implementing a robust quality control system involves monitoring every stage of the manufacturing process, from raw material sourcing to final product testing. This includes conducting regular inspections, performing batch testing, and using advanced analytical techniques to detect any defects or inconsistencies. Ensuring that your batteries meet industry standards and certifications is also essential for gaining customer trust and accessing global markets. Relevant certifications may include ISO 9001 for quality management, ISO 14001 for environmental management, and UN 38.3 for battery safety during transportation.

In addition to quality control, it is important to establish a traceability system that tracks the entire lifecycle of each battery, from production to end-use. This not only helps in identifying and addressing any issues that may arise but also enhances transparency and accountability. For beginners, investing in quality control and certification may require additional resources, but it is a crucial step in building a reputable and sustainable business.

Business Planning and Financial Considerations

Starting an EV battery manufacturing business requires careful planning and financial management. Developing a comprehensive business plan is essential for outlining your goals, strategies, and financial projections. Your business plan should include a detailed market analysis, product development roadmap, manufacturing process, marketing strategy, and financial plan. It should also identify potential risks and mitigation strategies. Securing funding is another critical aspect, as the initial investment in equipment, raw materials, and research and development can be substantial. Potential funding sources include personal savings, bank loans, venture capital, and government grants. Presenting a well-prepared business plan to potential investors or lenders can increase your chances of securing the necessary capital.

In addition to initial funding, it is important to plan for ongoing operational costs, such as labor, utilities, maintenance, and raw materials. Managing cash flow and maintaining a healthy financial position are essential for the long-term sustainability of your business. For beginners, it is advisable to start with a lean operation and gradually expand as you generate revenue and gain market traction. Partnering with experienced professionals or consultants can also provide valuable insights and guidance in navigating the complexities of the EV battery manufacturing industry.

Marketing and Distribution Strategy

Once your EV batteries are ready for the market, developing an effective marketing and distribution strategy is crucial for reaching your target customers and generating sales. Your marketing strategy should highlight the unique advantages of your EV batteries, such as high energy density, long cycle life, and safety features. Emphasizing these benefits can help differentiate your product from competitors and attract customers looking for reliable and high-performance batteries. Utilizing digital marketing channels, such as social media, search engine optimization (SEO), and content marketing, can help you reach a wider audience and build brand awareness.

In addition to online marketing, participating in industry trade shows and conferences can provide valuable opportunities to showcase your products, network with potential customers, and stay informed about the latest trends and developments. Establishing partnerships with automotive manufacturers, energy storage companies, and distributors can also help you expand your market reach and increase sales. For beginners, it is important to focus on building strong relationships with early adopters and gathering feedback to continuously improve your product and customer experience.

Future Trends and Innovations in EV Battery Manufacturing

The field of EV battery manufacturing is continuously evolving, with new innovations and advancements emerging regularly. One of the key trends is the development of solid-state batteries, which replace the liquid electrolyte with a solid electrolyte. Solid-state batteries offer several advantages, including higher energy density, improved safety, and longer lifespans. Another trend is the use of silicon anodes, which offer higher energy density compared to traditional graphite anodes. Additionally, the integration of artificial intelligence (AI) and machine learning (ML) in battery management systems (BMS) is expected to grow, enabling more efficient monitoring and optimization of battery performance.

For beginners, staying informed about these trends and incorporating them into your product development strategy can provide a competitive edge and position your business as a leader in the EV battery industry. Collaborating with research institutions and industry experts can also provide access to cutting-edge knowledge and resources, helping you stay at the forefront of innovation.

Conclusion

Starting an electric vehicle battery manufacturing business is a forward-thinking venture that taps into the growing demand for sustainable and high-performance energy storage solutions. EV batteries offer numerous advantages, including high energy density, long cycle life, and safety features, making them an attractive option for automotive manufacturers and energy storage companies. By understanding the key components and manufacturing process, conducting thorough market research, and implementing robust quality control and certification systems, you can build a successful and sustainable business. Developing a comprehensive business plan, securing funding, and creating an effective marketing and distribution strategy are essential steps in launching your business. As the field of EV battery manufacturing continues to evolve, staying informed about new trends and innovations will be crucial for maintaining a competitive edge. With careful planning, dedication, and a commitment to innovation, you can establish a thriving EV battery manufacturing business that contributes to the future of sustainable transportation.