Rasgulla Manufacturing and Canning : Project Report for Bank Loan

In the world of Indian sweets, Rasgulla is a timeless treat that brings joy and celebration to our taste buds. These spongy, sweet balls floating in sugar syrup hold a special place in our hearts. Let's dive into the interesting journey of making and packing Rasgullas, where tradition meets modern ways to bring this sweet delight to life.

The India Packaged Sweets market is set to reach INR 25,970.8 Crore by 2032, exhibiting a robust CAGR of 16.67% from 2024 to 2032, marking a significant milestone in its trajectory.

Making Rasgullas - Overview

Good Ingredients and Skilful Cooking

To start, we pick top-notch ingredients like chhena (paneer), sugar, and a hint of cardamom. Skilful hands then mix and shape the chhena into small, round balls. This step needs a gentle touch to get the perfect texture – soft yet a bit bouncy.

The Magic of Cooking

Now comes the magic part – cooking! The chhena balls swim in sweet syrup and transform into the spongy Rasgullas we love. This step needs some know-how to make sure each Rasgulla is just right.

Tradition Meets Tech

Today, technology has joined hands with tradition to make Rasgullas. Machines help mix, control temperatures, and shape the sweet treats. This makes it easier to produce lots of Rasgullas while keeping the authentic taste. But some places still stick to the old ways, keeping the soul of Rasgulla-making alive.

Packing the Sweetness - Keeping Things Fresh

Once the Rasgullas are perfect, we pack them to keep them fresh. The sweet orbs are sealed tight, so they stay juicy and tasty for a longer time. This lets Rasgullas travel far and wide, bringing joy to sweet lovers everywhere.

Smart Packing Tricks

Modern packing tricks help keep Rasgullas tasty during their journey. Sealing them in a vacuum, flushing out air, and using high-tech sterilization methods all play a part. These smart moves help Rasgullas keep their yummy taste and texture, no matter where they go.

Starting a Canned Rasgulla Business

Rasgulla, also known as Roshogolla, is a beloved Indian syrupy sweet, and while traditionally biodegradable, the innovation of canned Rasgulla has extended its shelf life considerably. In this article, we delve into the steps involved in starting a canned Rasgulla making business.

Embarking on a canned Rasgulla venture is a lucrative opportunity with moderate capital investment. The business, driven by the perennial popularity of Rasgulla, particularly in regions like West Bengal, Bihar, Odisha, North India, and even South India, offers high-profit potential. To ensure success, a steady supply of fresh milk to the production plant is crucial.

Steps to Start a Rasgulla Manufacturing Business:

Market Potential of Rasgulla:

Rasgulla enjoys high demand nationwide, especially in specific regions like West Bengal, Bihar, Odisha, North India, and has gained popularity even in South India. Canned Rasgulla, with its hygienic preparation and extended shelf life, holds even greater appeal. While many sweet shops outsource their products, focusing on the canned variant adds a value-added dimension and increased profitability.

Rasgulla Manufacturing Plant & Machinery:

Acquiring the right space is pivotal, with 1000 sq ft being sufficient for a small-scale plant. As the business expands, more space may be required, along with the provision of electricity and water. Necessary machinery includes stainless steel steam jacketed tanks, plate heat exchangers, sugar syrup preparation kettles, milk boiling kettles, canning retorts, and various other equipment to streamline the manufacturing process.

Rasgulla Manufacturing Process & Raw Materials:

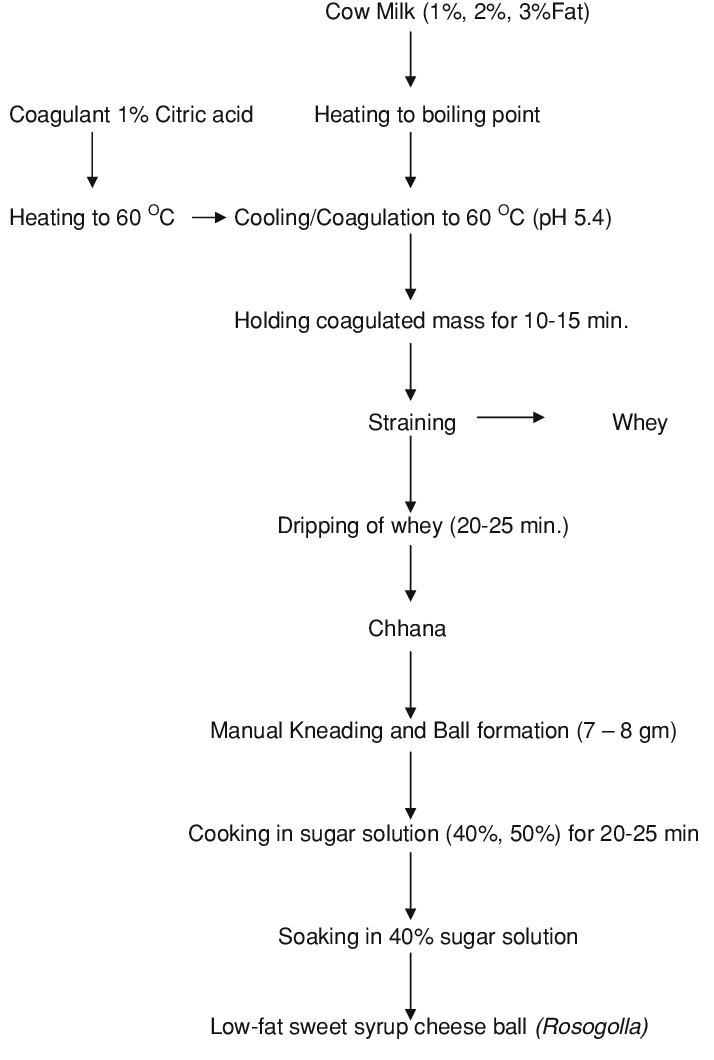

The production process involves several steps, starting with the preparation of Chhanna, followed by mixing and kneading. Sugar syrup preparation is a critical step, and the cooking of raw Rasgulla is meticulously carried out. The final product is prepared by draining the ripe Rasgulla, dipping it in sugar syrup, and adding essence for flavor. The canned Rasgullas are then filled, sealed, and processed in a retort for preservation.

The Rasgulla manufacturing process involves several key steps:

- Chhanna Preparation: Heat milk, add citric acid or lemon juice, and separate the curd. Extract the whey and form "chhanna" by pressing and cooling.

- Mixing and Kneading: Blend and knead the chhanna to achieve a soft and smooth consistency. Shape the mixture into small round balls.

- Sugar Syrup Preparation: Prepare sugar syrup with the right density, a crucial factor in Rasgulla-making.

- Cooking of Raw Rasgulla: Boil the raw Rasgulla in syrup until they are sufficiently thick. Gently flip them for even cooking.

- Final Product Preparation: Drain the ripe Rasgulla, dip them in sugar syrup, and add essence for flavor.

- Canning: Fill sterilized cans with Rasgullas, seal them immediately, and process in a retort for preservation.

Raw Materials for Rasgulla Making:

The primary raw material is fresh milk, necessitating a regular and reliable supply. Sugar, citric acid, and essence are also vital ingredients. Packaging materials like cans, labels, and cartons are essential for the presentation and storage of the Rasgulla.

Starting a canned Rasgulla business is not just a venture into the sweet business; it's a journey into the rich culinary heritage of India, where tradition meets innovation to create a timeless treat enjoyed by sweet enthusiasts across the country.

Emerging Trends in the Packaged Sweets Market in India:

The dynamics of the India Packaged Sweets market are undergoing notable shifts, primarily fueled by the substantial growth in the packaging sector. Embedded deeply in Indian culture, packaged sweets hold a pivotal role in cultural and social gatherings such as festivals, celebrations, and weddings. The evolving landscape of urbanization and changing dietary habits is contributing to a heightened consumption of packaged food products, including sweets.

Urbanization, coupled with a transformation in food consumption patterns, has led to a growing preference for ready-to-eat and packaged sweets, diverting attention from traditional or homemade variants. The surge in awareness regarding food hygiene and cleanliness further propels the demand for packaged sweets, as consumers increasingly opt for convenient, pre-packaged options.

An intriguing facet of this market evolution is the introduction of sugar-free sweets tailored for individuals with diabetes, broadening the consumer base. Manufacturers are not only catering to health-conscious consumers but also adopting customer-centric strategies like free home delivery and promotional offers, effectively boosting sales.

Moreover, ongoing innovations in processing techniques aimed at extending the shelf life of packaged sweets have become instrumental in shaping market trends. The emergence of luxurious brands offering organic, vegan, and dairy-free sweets, characterized by clean label ingredients, adds a sophisticated touch to the market landscape.

Looking ahead, the India Packaged Sweets market is poised to achieve a significant milestone, with a projected value of INR 25,970.8 Crore by 2032. This journey is anticipated to unfold with a compelling Compound Annual Growth Rate (CAGR) of 16.67% during the forecast period from 2024 to 2032. The market's future trajectory appears promising, reflecting the dynamic interplay of cultural traditions, changing consumer preferences, and innovative industry responses.