Suction Pipe/Rubber Hose Pipe Manufacturing Business and Market Forecast

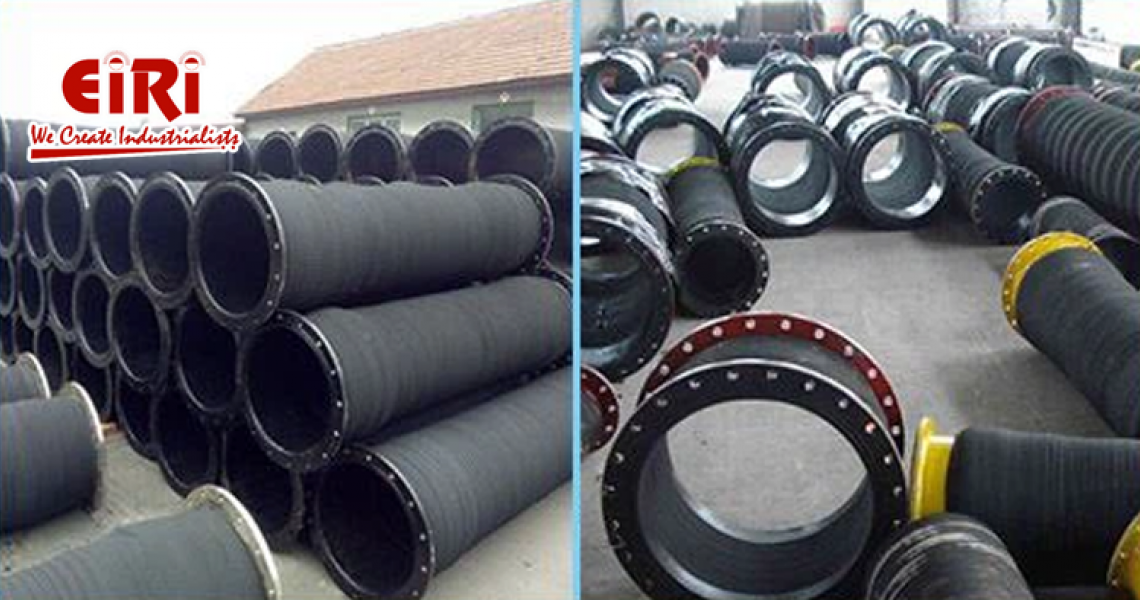

In the intricate world of fluid dynamics, the role of suction pipes is paramount, serving as the lifeline that pulls water from various sources against the relentless force of gravity. This necessitates a specialized design to withstand the challenges posed by different water sources, pressures, and flow velocities. One of the key players in this domain is the manufacturing of rubber hose and suction pipes, engineered to navigate the complexities of fluid transportation with precision and durability.

Suction, the process of pulling water from a source to the surface, requires pipes that transcend conventional limitations. While regular PVC pipes find their stride in ground operations with limited velocity, the demands of well, bore, or elevated water sources call for a different breed. Suction pipes come into play when the velocity exceeds the standard 1.5 m/s, reaching up to 3 m/s, inducing turbulent flow. This shift demands a higher echelon of quality, flexibility, and resilience in the face of internal and external pressures.

At the heart of the rubber hose and suction pipe manufacturing business lies the art of creating conduits that embody quality and flexibility. These pipes are meticulously designed to tackle the intricacies of turbulent flow, offering a solution where standard PVC pipes fall short. The manufacturing process involves the fusion of cutting-edge technology and engineering finesse to craft pipes that can withstand the forces exerted upon them.

Water sources vary in their nature, presenting unique challenges for suction pipes. A robust manufacturing process considers these variations, tailoring pipes to meet the specific demands of wells, boreholes, or alternative sources. The flexibility of these pipes allows them to seamlessly adapt to different environments, ensuring efficient water extraction against the pull of gravity.

Market dynamics of Rubber Hose Pipe

In the ever-evolving landscape of global commerce, the hose pipe market has emerged as a dynamic force, showcasing a trajectory of substantial growth. With a valuation of $18.7 billion in 2020, the market is projected to ascend to $32.3 billion by 2032, charting a noteworthy CAGR of 4.4% from 2023 to 2032. Heralded as a flexible conduit crafted from rubber or plastic, a hose is a versatile hollow tube engineered to convey fluids across diverse locations. Often interchangeably referred to as pipes, hoses find applications across multifarious end-user industries, including construction, automotive, agriculture, food & beverage, and oil & gas.

The impetus for market expansion is notably propelled by heightened construction activities globally. With burgeoning investments in infrastructure development, particularly in developed economies like the U.S., the growth trajectory of the hose pipe market is intricately linked to the pulse of global construction initiatives. Governmental fervor in augmenting sports infrastructure further fuels this upward trend. As construction activities surge worldwide, the demand for hydraulic-based construction equipment such as excavators, hydraulic cranes, and loaders experiences a parallel escalation, thus catalyzing the growth of the hose pipe market.

The technological metamorphosis within core construction and infrastructure industries is another catalyst envisaged to elevate the demand for hose pipes. Beyond the construction realm, burgeoning requirements in the agricultural, construction, and industrial sectors contribute significantly to the market's upward spiral. The agricultural sector, driven by an intensified demand for food production, witnesses an augmented reliance on hose pipes to enhance crop yield. Simultaneously, in the construction sector, these versatile conduits play a pivotal role in the transfer of water, fuel, air, and construction materials.

The market's ascent is further underlined by a confluence of factors, including the surge in demand for hydraulic gears spurred by escalating construction activities, an uptick in the need for material handling equipment, a growing appetite for innovative agricultural machinery, and the increasing adaptability of various industries to hydraulic equipment. As the hose pipe market journeys forward, it encapsulates not just a conduit for fluids but a conduit for the evolving needs and aspirations of diverse industries, navigating the currents of progress with resilience and adaptability.

Market Drivers:

Advances in the Oil and Gas Field

The colossal footprint of the oil and gas industry makes it a pivotal driver propelling the global industrial hose market forward. This sector stands as the primary adopter of industrial hoses, providing a robust impetus for market expansion. Notably swift in embracing technological advancements, the oil and gas industry serves as a key target for innovative hose solutions. Consequently, the majority of product releases within the hose market are strategically tailored to cater to the evolving needs of oil firms.

Rising PVC Material Demand

A fundamental force steering the global industrial hose market is the escalating demand for polyvinyl chloride (PVC). Positioned as one of the most commonly used plastics, PVC is synthesized through the polymerization of vinyl chloride monomer. The chlorine component, integral to PVC, is sourced from industrial-grade salt, while the carbon content is derived from ethylene addition to oil or gas. This surge in PVC demand significantly influences the trajectory of the industrial hose market.

In recent times, PVC-based industrial hoses have risen to prominence across diverse industries such as automotive, pharmaceuticals, infrastructure, oil and gas, food and beverages, mining, water, agriculture, and more. These hoses, crafted from PVC material, have become integral for the manufacturing and utilization of tubes and pipes, facilitating the seamless transportation of air, water, chemicals, and fluids from one endpoint to another.

The burgeoning demand for PVC hoses is attributed to their versatile applications encompassing air, abrasive products, mineral oils, water, technical and domestic gases, steam, fuels, and various others. This increasing demand is a testament to the broad spectrum of roles these hoses play in diverse industrial operations. Technological advancements further augment the growth of the industrial hoses market by continually enhancing the capabilities of these indispensable components.

Elevated Need for Resilient Industrial Hoses in Critical Applications

The application spectrum of industrial hoses spans the movement of fluids, chemicals, air, water, oil, and other materials from one location to another. There exists a substantial demand for robust industrial hoses, particularly in critical applications characterized by high temperatures, elevated pressures, chemical reactions, and vacuum conditions.

When selecting hoses, customers are urged to consider a myriad of crucial criteria, including resistance to catastrophic failure, permeability, chemical compatibility, temperature tolerance, external environmental factors, vacuum resilience, and more. To meet these exacting demands, major players in the market are consistently introducing cutting-edge products tailored for mission-critical applications. This influx of innovative solutions is propelling the demand for durable hoses within the industry, addressing the specific needs of diverse operations.

Market Restraints:

Lack of Technicians

Despite the burgeoning demand for industrial hoses, a notable hindrance lies in the scarcity of technicians well-versed in the intricacies of these specialized components. The limited accessibility to end consumers becomes a bottleneck in the global industrial hose market's growth trajectory. The shortage of skilled technicians creates a gap, hindering the seamless integration and widespread application of industrial hoses.

Market Challenges:

Lack of Product Differentiation

A formidable challenge confronting manufacturers in the industrial hose market is the lack of product differentiation. This scenario is compounded by the availability of inexpensive local variants and a dearth of diverse product offerings, particularly in unorganized emerging-country markets. Consequently, existing manufacturers face the pressure to slash prices, leading to profit constraints and subdued value growth. Overcoming this challenge demands innovative strategies to enhance product distinctiveness and carve out a niche in the competitive market landscape.

Conclusion

The primary catalyst behind the upward surge in the global industrial hose market is the escalating demand for polyvinyl chloride (PVC). Additionally, the imperative need for water supplies in the agriculture sector has been a pivotal factor contributing to the remarkable growth of the global industrial hose market. In the landscape of this thriving industry, the Asia Pacific region has emerged as the leader, capturing a substantial 36.2% share of market revenue in the year 2022.

The industrial hose market encompasses a global industry dedicated to the production and distribution of various hose types, predominantly utilized in industrial settings. These hoses are meticulously crafted to transport fluids or gases under conditions of high pressure or extreme temperatures, finding widespread applications in diverse sectors including oil and gas, chemical, food and beverage, agriculture, construction, and mining.

The market's trajectory is steered by the escalating growth in various end-use industries and the mounting demand for hoses capable of withstanding harsh operating conditions efficiently. Additionally, the surge in demand is fueled by the quest for advanced materials and technologies that can elevate the performance and reliability of hoses while mitigating the risks associated with leaks and failures.

Projections indicate that the industrial hose market is poised for continued expansion in the coming years, driven by factors such as the increasing industrialization in developing countries, a rising demand for energy and water resources, and the growing integration of advanced materials and technologies in hose manufacturing. However, the market may encounter challenges in the form of fluctuating conditions, requiring adept navigation to sustain its upward trajectory.